EXTRUSION OF PLASTICS

EXTRUSION OF PLASTICS

Materials such as polystyrene, nylon, polypropylene and polythene can be used in a process called extrusion. These are thermoplastics - this means when they are heated and then pressured in a mould they can be formed into different shapes and sections

A machine used to extrude materials is very similar to the injection moulding machine. A motor turns a thread which feeds granules of plastic through a heater. The granules melt into a liquid which is forced through a die, forming a long 'tube like' shape. The extrusion is then cooled and forms a solid shape. The shape of the die determines the shape of the tube.

The animation below shows a close up of the steel die. The hole in its centre is a hexagon. This means that the fluid plastic forms a hexagonal section when it is forced through the hole. Dies can be manufactured to almost any section / shape, including tubes.

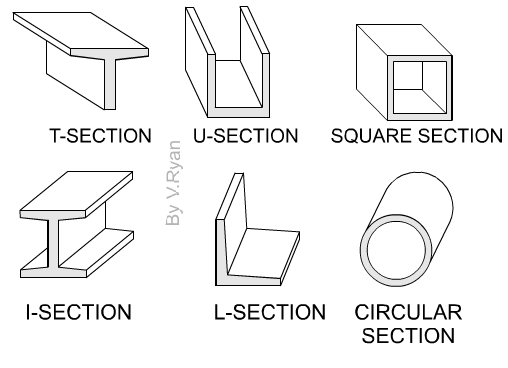

Below are examples of the type of shapes (sections) that can be extruded using an extrusion machine.