How Extruder Works?

How Extruder Works?

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. It is generally used by list of pvc extrusion manufacturers to produce different types of plastic materials.

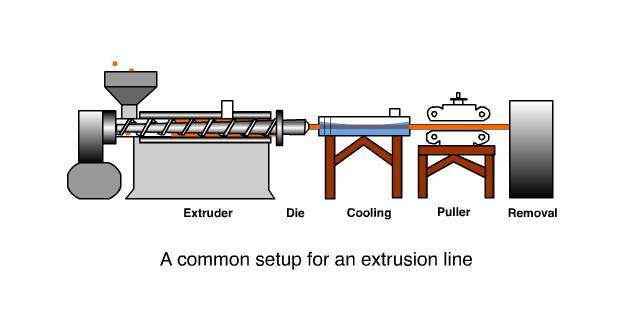

A picture of an extruder manufacturing line is shown above. First, raw material, in the form of small plastic pellets, is placed in the hopper. The hopper rests on top of the barrel. The barrel is a heated hollow steel cylinder, sort of like a really thick pipe. An auger-type screw rotates inside of the barrel. The screw’s rotation takes the plastic pellets and pushes them forward, into the barrel. As the pellets move towards the front of the barrel, frictional and electrical heat from the barrel melt the plastic. After the plastic is melted, the rotating screw continues to act as a pump and forces the molten plastic through a die. The die is usually a piece of steel with the shape of the desired part machined into it. Once the melted plastic exits the die, it is shaped like the finished product. Next, it is pulled through some sort of cooling apparatus, which usually cools with air or water. Once cool, the product can be rolled up, cut into sections, packaged, or can go on to secondary operations.

Extrusion machinery can be complicated to operate, but the overall process is relatively straightforward. The heart of the machine is the screw, which sometimes is referred to as an auger. The screw is turned by a gearbox, which is powered by a motor. It is enclosed in a tight, heated barrel, which helps to provide friction.

The thermoplastic pellets are delivered into the machine through a hopper. The hopper is located at the rear of the barrel/screw assembly and the pellets drop into the barrel from there. As the screw turns, it slowly drags the thermoplastic pellets forward. The heat from the friction of the screw turning inside the barrel–along with external heating–melts the plastic as it moves forward in the barrel. The melted plastic is pushed into a section designed to meter the plastic for the next stage in the process. It also may be subjected to pressurized pumping at this phase of the process.

Once the plastic has entered into metering section of the barrel, it is ready to be extruded into a die. The die is attached to the barrel and it represents the final shape or profile that the plastic is intended to take. The plastic is forced into the die. As the plastic moves forward into the die, it will be separated by a mandrel, which is centered in the extrusion channel.

Pressurized air is forced though the mandrel structure as a means of keeping the plastic from collapsing as it moves through the die. As the plastic leaves the die, it will enter into a vacuum environment. Inside the vacuum, there are sizing rings meant to keep the plastic in the desired shape. The vacuum environment also will be filled with water as a means of cooling the extruded plastic. After the extruded plastic has passed through the water-filled vacuum environment it can be cut or spooled as appropriate.