What is Impact Extrusion?

What is Impact Extrusion?

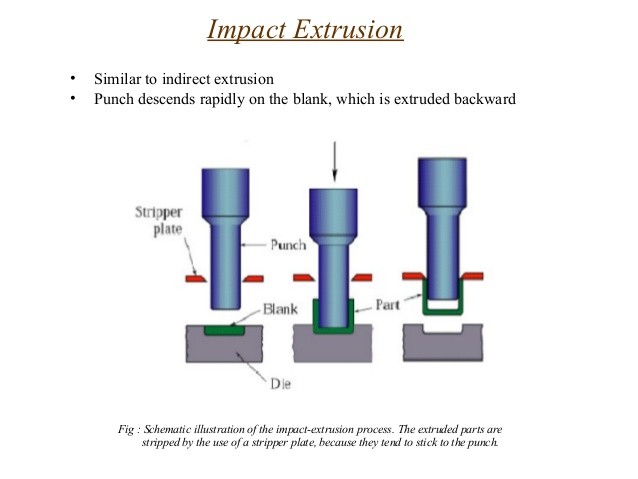

Impact extrusion is a metalforming technique where a technician places a slab of metal into a press and applies pressure to force the metal to conform with a punch or die. This is an example of cold forming, where people shape metal without heating it, and is commonly used with metals like aluminum. Numerous companies produce generic parts using this method and can also fill custom orders by request, typically requiring a minimum to compensate for the costs of producing the custom mold.

The first step in the process involves tumbling the metal slugs to cover them with a lubricant. Then, the technician can position them in the die. Some systems are automated and do not require a technician to handle the metal. After the pressure forms the product, it may be ready for use or the technician could need to trim or otherwise finish it. The stress of the impact can create small cracks and designers have to make sure molds and pressures are appropriate to avoid creating products with weak spots.

In forward impact extrusion, the pressure forces the metal into a mold. Reverse or backward impact extrusion forms metal around a punch. A combination method mixing elements of both is also available. These techniques can create metal discs, cylinders, and a wide variety of other shapes for use in manufacturing processes. It is possible to reuse the forms numerous times and factories can maintain archives of old forms for future use.

Companies offering impact extrusion may specialize in parts for specific industries or could produce a broad range of products. In all cases, they use careful quality control processes during production to make sure their metal parts form correctly. They can employ materials testing companies to periodically evaluate finished parts for stress cracks and other problems, and use inspection personnel to walk the manufacturing floor and check for any irregularities.

When someone needs a custom impact extrusion, the cost can vary, depending on the project and the company. Companies may charge a fee based on the number of pieces the client orders, embedding the cost of producing the mold in this fee. Others charge to make the mold and then charge per piece. People can shop around between companies to find out more about pricing options and get an idea of which company would be most likely to meet their needs. Trade publications may include company overviews and reviews to help people select manufacturers.